| Availability: | |

|---|---|

| Quantity: | |

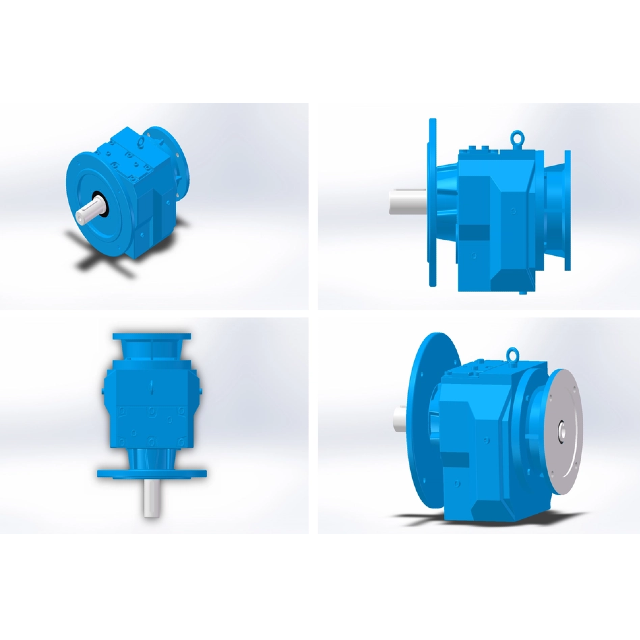

RX57

TAIXING

TAIXING's R Series High-Quality Inline Helical Gear Reducer is a premium power transmission solution designed for industrial efficiency and durability. Built on advanced modular technology, it offers a wide range of power outputs (0.18-160kw) and torque capacities (up to 18000N.m), catering to the needs of high-performance equipment across sectors. Its helical gearing design ensures smooth power transfer, while high-quality materials and precision manufacturing guarantee long-term reliability. As a trusted industrial gear reducer, it combines flexibility, efficiency, and robustness to drive productivity in diverse applications.

The reducer’s compact structure integrates high-strength components, making it ideal for space-constrained equipment such as automated production lines and compact machinery. Its sturdy build supports heavy-duty operations without occupying excessive space, maximizing equipment design flexibility.

With optimized helical gear meshing, the reducer achieves industry-leading efficiency—96% for 2-stage (ratio: 5-24.8) and 94% for 3-stage (ratio: 27.2-264). This high efficiency reduces energy consumption, lowers operational costs, and contributes to environmental sustainability.

Precision-ground 20CrMnTi gears and carburized 40Cr shafts ensure minimal friction and vibration, resulting in low operational noise. This feature is particularly valuable for indoor applications such as food processing plants and workshops where noise control is critical.

The modular design enables diverse combinations of mounting types (Foot/Flange), input forms (IEC flange, motor direct connection, shaft input), and structural designs. This versatility allows seamless integration with different equipment, eliminating compatibility issues.

Cast Iron housing provides excellent impact resistance and heat dissipation, protecting internal components from damage.

Advanced heat treatment processes (carburizing, quenching) enhance gear and shaft durability, ensuring the reducer withstands continuous operation in harsh industrial conditions.

Parameter | Specifications |

Gearing Arrangement | Helical |

Maximum Output Torque | 18000N.m |

Rated Power Range | 0.18-160kw |

Maximum Input Speed | <2000r/min |

Output Speed Range | 0.16-1028r/min |

Gear Ratio | 1.3 - 196.41 |

Housing Material | Cast Iron |

Gear Material | 20CrMnTi (precision grinding) |

Shaft Material | 40Cr (carburizing & quenching) |

Mounting Options | Foot mounted, Flange mounted |

Input Methods | IEC flange, direct motor connection, shaft input |

Standard Colors | Blue RAL5010, Grey; custom colors available |

Warranty | 12 Months |

Size | Input Power Rating (kw) | Ratio Range | Max Torque (N.m) |

17 | 0.18–0.75 | 3.83–74.84 | 85 |

27 | 0.18–3 | 3.37–135.09 | 130 |

37 | 0.18–3 | 3.41–134.82 | 200 |

47 | 0.18–5.5 | 3.83–167.65 | 300 |

57 | 0.18–7.5 | 4.39–189.69 | 450 |

67 | 0.18–7.5 | 4.29–165.48 | 600 |

77 | 0.18–11 | 5.21–195.24 | 820 |

87 | 0.55–22 | 5.36–246.54 | 1550 |

97 | 0.55–30 | 4.49–264.42 | 3000 |

107 | 2.2–45 | 5.06–245.5 | 4300 |

137 | 5.5–55 | 5.15–223.34 | 8000 |

147 | 11–90 | 5.00–163.46 | 13000 |

167 | 11–160 | 8.77–196.41 | 18000 |

The reducer’s precise speed control and modular compatibility make it a core component of automated assembly lines, robotic arms, and precision machining equipment, ensuring consistent production quality and efficiency.

In construction machinery (e.g., concrete mixers, cranes) and metal processing equipment (e.g., cutting machines, stamping presses), the reducer’s high torque and durability handle heavy loads and frequent operation, supporting large-scale construction and manufacturing projects.

Resistant to corrosive environments and high temperatures, it is suitable for plastic extruders, chemical mixers, and material handling systems in chemical plants, ensuring stable operation in harsh chemical conditions.

It also serves Mining & Quarry (crushers, conveyors), Transport & Packaging (conveyor belts, packaging machines), and Crusher & Cement plants, demonstrating its adaptability to diverse industrial needs.

The reducer is certified by CE, SGS, and BV, confirming compliance with international quality, safety, and environmental standards. These certifications ensure it meets the requirements of global markets, facilitating cross-border trade.

12-month warranty covering all manufacturing defects, with free repair or replacement for qualified issues.

Dedicated technical support team providing 24/7 consultation on installation, operation, and maintenance.

Fast delivery of genuine spare parts to ensure minimal downtime for your equipment.

The gear ratio ranges from 1.3 to 196.41, covering both low-speed high-torque and high-speed low-torque applications, making it suitable for diverse industrial needs.

Yes, the Cast Iron housing and heat-treated components provide excellent heat resistance, allowing the reducer to operate reliably in temperatures common in industrial settings (e.g., cement plants, metal processing facilities).

With high-quality materials and precision manufacturing, the reducer typically offers a long service life (5-8 years under normal operation). Regular maintenance can further extend its operational lifespan.

It supports three input forms—IEC flange, direct motor connection, and shaft input—ensuring compatibility with most standard industrial motors, simplifying installation and integration.

Yes, it includes a 12-month warranty from the date of delivery, covering manufacturing defects. Our after-sales team provides timely support to resolve any issues during the warranty period.