| Availability: | |

|---|---|

| Quantity: | |

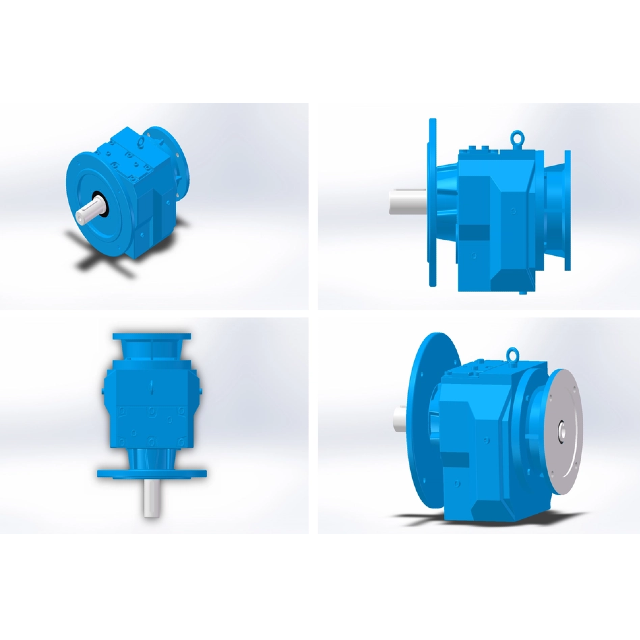

RX57

TAIXING

The TAIXING R Series Inline Helical Gear Reducer is engineered with a highly standardized modular design, redefining flexibility and reliability in industrial power transmission. This gear reducer integrates advanced helical gearing technology, premium materials, and precision manufacturing to deliver consistent performance across diverse heavy-duty applications. Its core value lies in balancing high torque output, energy efficiency, and compact dimensions, making it a preferred choice for industries requiring stable speed reduction and power conversion.

Modular configuration enabling multiple combinations and mounting options

Wide power range (0.18-160kw) and high torque capacity (up to 18000N.m)

Excellent transmission efficiency (up to 96%) for energy savings

Durable construction with precision-machined components

Low noise operation and strong load-bearing capabilities

The modular gear reducer design allows for flexible combinations of mounting types (foot mounted, flange mounted) and input forms (IEC flange, direct motor connection, shaft input). This versatility eliminates the need for custom modifications, reducing installation time and adapting seamlessly to various industrial equipment layouts.

Crafted with 20CrMnTi grinding gears (for wear resistance and precision), 40Cr carburized-quenched shafts (for high strength and toughness), and cast iron housing (for stability and heat dissipation), the gear reducer ensures long service life and reliable operation even in harsh working environments. Precision grinding of gears minimizes friction and noise, enhancing overall performance.

With a maximum output torque of 18000N.m and a rated power range of 0.18-160kw, this high-torque inline helical gear reducer handles both light and heavy-duty applications effortlessly. From small conveyors to large mining equipment, it delivers consistent power transmission without compromising efficiency.

Equipped with optimized helical gearing, the reducer achieves 96% efficiency for 2-stage models (ratio 5-24.8) and 94% for 3-stage models (ratio 27.2-264). This energy-saving performance reduces operational costs and aligns with industrial sustainability goals.

The compact gear reducer design saves valuable installation space while maintaining high structural strength. Its robust build withstands vibration and impact, ensuring a long service life (exceeding industry averages) and reducing maintenance frequency.

Precision-machined helical gears and high-quality bearings minimize operating noise, creating a quieter working environment. The stable transmission ensures smooth speed regulation, protecting downstream equipment from sudden load fluctuations.

Parameter | Specification |

Gearing Arrangement | Helical |

Rated Power Range | 0.18-160kw |

Maximum Output Torque | Up to 18000N.m |

Input Speed | Less than 2000r/min |

Output Speed Range | 0.16-1028r/min |

Transmission Ratio | 1.3 - 196.41 |

Housing Material | Cast Iron |

Gear Material | 20CrMnTi (with grinding) |

Shaft Material | 40Cr (with carburizing and quenching) |

Mounting Types | Foot mounted, Flange mounted |

Input Forms | IEC flange, direct with motor, shaft input |

Color Options | Blue RAL5010, Grey, or custom colors |

Warranty Period | 12 Months |

Size | Input Power Rating (kw) | Ratio Range | Max Torque (N.m) |

17 | 0.18–0.75 | 3.83–74.84 | 85 |

27 | 0.18–3 | 3.37–135.09 | 130 |

37 | 0.18–3 | 3.41–134.82 | 200 |

47 | 0.18–5.5 | 3.83–167.65 | 300 |

57 | 0.18–7.5 | 4.39–189.69 | 450 |

67 | 0.18–7.5 | 4.29–165.48 | 600 |

77 | 0.18–11 | 5.21–195.24 | 820 |

87 | 0.55–22 | 5.36–246.54 | 1550 |

97 | 0.55–30 | 4.49–264.42 | 3000 |

107 | 2.2–45 | 5.06–245.5 | 4300 |

137 | 5.5–55 | 5.15–223.34 | 8000 |

147 | 11–90 | 5.00–163.46 | 13000 |

167 | 11–160 | 8.77–196.41 | 18000 |

Ideal for belt conveyors, chain conveyors, and bucket elevators, the inline helical gear reducer provides stable speed reduction for continuous material transport in warehouses, ports, and manufacturing plants.

Withstands heavy loads and harsh conditions in mining equipment such as crushers, screeners, and excavators, delivering reliable power transmission for ore extraction and processing.

Fit for crushers, cement mixers, and rotary kilns, offering high torque output to handle the intensive workload of aggregate crushing and cement production.

Meets hygiene and stability requirements for food processing lines (e.g., packaging machines, conveyor systems) and beverage production equipment, ensuring smooth operation without contamination risks.

Used in construction machinery (e.g., concrete mixers, lifts) and metal processing equipment (e.g., cutting machines, stamping presses), providing precise speed control and high load capacity.

The TAIXING R Series Inline Helical Gear Reducer is certified by CE, SGS, and BV, complying with international quality and safety standards. These certifications validate its reliability, environmental friendliness, and compatibility with global industrial applications.

12-month warranty covering manufacturing defects and component failures

Professional technical consultation for installation, operation, and maintenance

Fast replacement of spare parts (gears, shafts, bearings) to minimize downtime

Customization services for special requirements (color, mounting, torque)

The reducer supports two main mounting types: foot mounted (for stable floor installation) and flange mounted (for direct attachment to equipment frames), adapting to different installation spaces and load requirements.

The maximum input speed is less than 2000r/min, ensuring safe and efficient transmission without overheating or component damage.

Under normal operating conditions, routine maintenance (oil change, inspection of gears and bearings) is recommended every 6-12 months. Harsh environments may require more frequent checks.

Yes, standard colors include Blue RAL5010 and Grey, and custom colors are available upon request to match your equipment or factory aesthetics.

The cast iron housing and high-temperature resistant lubricants enable the reducer to operate in environments up to 80℃. For extreme temperatures, please consult our technical team for customized solutions.