| Availability: | |

|---|---|

| Quantity: | |

RX57

TAIXING

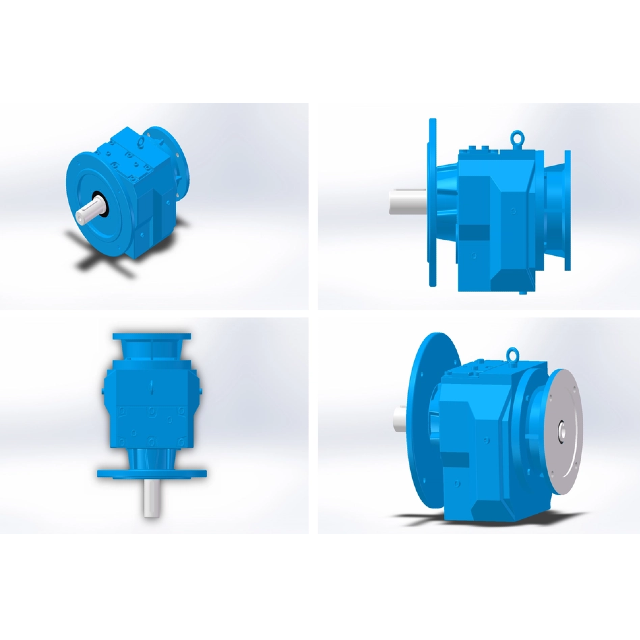

The TAIXING R Series Inline Helical Gear Reductor is a heavy-duty power transmission solution designed for industrial applications demanding high reliability, versatility, and efficiency. Built on a modular platform, this gear reductor integrates precision helical gearing, rugged materials, and advanced manufacturing processes to meet the diverse needs of sectors ranging from automation to mining. Its core industrial value lies in bridging the gap between motor power and load requirements, ensuring smooth speed reduction and torque amplification.

Wide speed ratio range (1.3-196.41) for precise speed control

Strong radial load capacity and compatible axial load performance

Long service life with low maintenance requirements

Multiple input/output configurations for seamless equipment integration

Compliance with international quality and safety standards

The industrial inline helical gear reductor features a modular design that supports various combinations of input forms (IEC flange, direct motor coupling, shaft input) and mounting types (foot, flange). This flexibility allows it to integrate with virtually any industrial equipment, from small automation machines to large-scale heavy machinery, reducing compatibility issues.

Each component is crafted for durability: 20CrMnTi precision-ground gears ensure minimal wear and smooth meshing, 40Cr carburized-quenched shafts provide exceptional strength, and cast iron housing offers superior stability and heat dissipation. Precision engineering eliminates backlash and reduces noise, enhancing operational efficiency.

With a rated power range of 0.18-160kw and maximum torque of 18000N.m, this heavy-duty gear reductor handles both light-load precision tasks and heavy-load industrial operations. The wide output speed range (0.16-1028r/min) makes it suitable for applications requiring both high-speed conveying and low-speed heavy lifting.

Optimized helical gear geometry ensures exceptional transmission efficiency: 96% for 2-stage models (ratio 5-24.8) and 94% for 3-stage models (ratio 27.2-264). This energy-saving performance lowers electricity consumption and reduces carbon footprint, aligning with modern industrial sustainability initiatives.

The compact inline helical gear reductor design saves installation space, making it ideal for equipment with limited layout room. Its rugged structure withstands vibration, impact, and harsh environmental conditions (dust, humidity), ensuring long service life and minimal downtime.

Precision grinding of gears and high-quality bearings result in low noise operation (≤75dB), creating a comfortable working environment. Stable transmission minimizes speed fluctuations, protecting downstream components and improving overall equipment performance.

The reductor offers large radial loading ability and axial load capacity of up to 5% of radial load, making it suitable for applications with high lateral forces (e.g., conveyors, mixers) and ensuring consistent performance under varying load conditions.

Feature | Details |

Gearing Type | Helical |

Rated Power | 0.18-160kw |

Maximum Output Torque | Up to 18000N.m |

Max Input Rotational Speed | <2000r/min |

Output Speed Range | 0.16-1028r/min |

Transmission Ratio | 1.3 - 196.41 |

Housing Material | Cast Iron |

Gear Material | 20CrMnTi (precision grinding) |

Shaft Material | 40Cr (carburizing and quenching) |

Mounting Options | Foot mounted, Flange mounted |

Input Configurations | IEC flange, direct motor connection, shaft input |

Standard Colors | Blue RAL5010, Grey, custom options available |

Warranty | 12 Months |

Size | Input Power Rating (kw) | Ratio Range | Max Torque (N.m) |

17 | 0.18–0.75 | 3.83–74.84 | 85 |

27 | 0.18–3 | 3.37–135.09 | 130 |

37 | 0.18–3 | 3.41–134.82 | 200 |

47 | 0.18–5.5 | 3.83–167.65 | 300 |

57 | 0.18–7.5 | 4.39–189.69 | 450 |

67 | 0.18–7.5 | 4.29–165.48 | 600 |

77 | 0.18–11 | 5.21–195.24 | 820 |

87 | 0.55–22 | 5.36–246.54 | 1550 |

97 | 0.55–30 | 4.49–264.42 | 3000 |

107 | 2.2–45 | 5.06–245.5 | 4300 |

137 | 5.5–55 | 5.15–223.34 | 8000 |

147 | 11–90 | 5.00–163.46 | 13000 |

167 | 11–160 | 8.77–196.41 | 18000 |

Integrates seamlessly with automated assembly lines, robotic arms, and conveyor systems, providing precise speed control and reliable power transmission for high-efficiency manufacturing.

Used in packaging machines, labeling equipment, and material transport systems, ensuring smooth and consistent operation for food, pharmaceutical, and consumer goods packaging.

Adapts to plastic extruders, injection molding machines, and chemical mixers, withstanding corrosive environments and high temperatures while delivering stable torque for material processing.

Ideal for metal cutting machines, welding equipment, and construction lifts, providing high torque output and precise speed regulation for heavy-duty metal processing and building operations.

Withstands the rigors of mining crushers, screeners, and ore transport systems, delivering reliable power in dusty, high-vibration environments to ensure continuous operation.

The TAIXING R Series Inline Helical Gear Reductor holds CE, SGS, and BV certifications, confirming compliance with EU safety standards, quality management systems, and environmental regulations. These certifications ensure global market access and customer confidence.

12-month warranty covering all manufacturing defects and component failures

Dedicated technical support team for installation guidance and troubleshooting

Fast delivery of genuine spare parts to minimize equipment downtime

Customization services for special applications (e.g., extreme temperatures, unique mounting)

The reductor is compatible with IEC standard motors, AC motors, and DC motors, supporting direct motor coupling, IEC flange connection, and shaft input for flexible integration.

The transmission ratio ranges from 1.3 to 196.41. Choose the ratio based on your motor speed and required output speed (output speed = input speed ÷ ratio). Our technical team can assist with ratio selection.

Gears are made of 20CrMnTi (precision-ground) for wear resistance and strength, while shafts are 40Cr (carburized-quenched) for toughness and load-bearing capacity—ensuring durability in heavy-duty applications.