Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

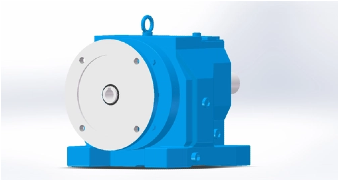

Selecting the proper Industrial Inline Helical Gear Reductor is a critical step in optimizing the performance of conveyor systems. At Taixing, we understand the importance of matching gearbox specifications to your conveyor's load, speed, and operational environment. This guide provides a step-by-step checklist to help procurement and plant engineers make informed decisions, short-list suitable models, and request accurate quotes based on their system requirements. Choosing the right reducer ensures smoother operation, reduced downtime, and better energy efficiency.

Before evaluating gearbox models, it’s essential to understand the mechanical demands of your conveyor system. A thorough assessment of torque requirements and duty cycles ensures reliable operation and extends the lifespan of the Industrial Inline Helical Gear Reductor.

Torque is the driving force a gearbox must provide to move a conveyor efficiently. Calculating the required torque involves multiplying the load by the pulley radius while factoring in friction losses and inclined surfaces. A simplified formula can be expressed as:

Torque (Nm) = (Load (kg) × Gravity (9.81 m/s⊃2;) × Pulley radius (m)) × Safety Factor

The safety factor accounts for unexpected load fluctuations or shock conditions, typically ranging from 1.2 to 1.5 for standard conveyors. Additionally, considering seasonal variations or changes in material flow can help prevent under-sizing. Using this calculation allows engineers to avoid undersized gear reducers, which can lead to premature failure, increased wear, or operational downtime.

Duty cycles describe how frequently and intensively the conveyor operates. Recognizing these patterns helps select a gearbox designed for specific operational demands:

Continuous duty: Gearboxes run constantly at steady loads, requiring robust bearings and lubrication systems.

Intermittent duty: Short operational periods with frequent stops. Gear reducers must handle start-stop stress without overheating.

Shock loads: Sudden surges in torque due to uneven loading or emergency stops. These conditions demand higher safety factors and reinforced gears.

Properly matching your Industrial Inline Helical Gear Reductor to the duty cycle prevents premature wear, reduces maintenance, and improves overall efficiency. In high-impact environments, it is also beneficial to monitor vibration and temperature to anticipate maintenance needs.

A gearbox’s speed reduction ratio, number of stages, and mounting style influence its performance and compatibility with the conveyor system.

The speed-to-torque tradeoff is central to choosing the right ratio. A higher reduction ratio increases torque but reduces output speed, while a lower ratio maintains speed but limits torque. To select an optimal ratio:

Determine the conveyor’s required speed (m/s or rpm).

Calculate the output torque from your load and pulley radius.

Select a gearbox ratio that meets torque requirements without overloading the motor.

Using real-world examples, a conveyor handling heavy bulk materials may need a 10:1 reduction, while a lightweight packaging line may operate efficiently with a 5:1 ratio. Proper ratio selection ensures smooth operation, energy efficiency, and longevity of both the conveyor and the gear reducer.

Industrial Inline Helical Gear Reductors are versatile in mounting. Common options include:

Foot-mounted: Provides stable base support for horizontal conveyors.

Flange-mounted: Ideal for direct connection to motor shafts or equipment.

Shaft-mounted: Reduces footprint and aligns directly with conveyor shafts.

Taixing’s R-series modular inline helical gearboxes offer flexible mounting options, allowing engineers to integrate gear reducers efficiently into diverse conveyor layouts without requiring extensive redesign. Modular design also simplifies maintenance and spare parts replacement.

The operational environment significantly impacts gearbox selection. Dust, moisture, chemicals, and temperature variations can degrade performance if the gear reducer is not properly specified.

Ingress Protection (IP) ratings indicate a gearbox’s resistance to dust and water. For food, beverage, or chemical lines, stainless steel or coated housings provide enhanced corrosion resistance. Selecting an Industrial Inline Helical Gear Reductor with appropriate IP protection prevents contamination, reduces maintenance, and extends service life.

Gearboxes operating in high-temperature or dusty environments must have suitable lubrication and sealing systems. Washdown areas require corrosion-resistant seals to prevent water ingress. Additionally, considering local climatic conditions—such as high humidity or extreme temperatures—can prevent overheating and oil degradation. Evaluating these conditions ensures reliable operation, minimizes downtime, and protects internal components from premature wear.

Evaluating efficiency and maintenance requirements is crucial to understanding the total cost of ownership. A well-chosen Industrial Inline Helical Gear Reductor can deliver long-term savings through reduced energy consumption and lower maintenance costs.

Helical gearboxes, including inline models, are generally more efficient than worm gear reducers due to their tooth engagement design. Higher efficiency translates into lower energy consumption for continuous operation. For example, replacing a worm gearbox with an inline helical unit can reduce energy costs while maintaining the same torque output. Over the lifespan of a conveyor system, these efficiency gains can significantly impact operational budgets.

Ease of maintenance impacts operational continuity. Gearboxes with modular components, readily available spare parts, and standardized designs minimize downtime. Regular service intervals, lubrication schedules, and clear maintenance instructions are critical for keeping conveyor systems running efficiently. Including condition monitoring tools can further extend service life by predicting failures before they occur.

When evaluating a gearbox, consider:

Energy consumption differences for intended duty cycles

Risk and cost of unscheduled downtime

Spare parts availability and lead times

Maintenance labor requirements

Expected service life under operational conditions

Considering these factors provides a holistic view of investment beyond initial purchase costs, helping procurement teams make financially sound decisions.

Engaging suppliers with clear technical inquiries ensures the selected Industrial Inline Helical Gear Reductor meets system demands and quality expectations.

When requesting quotes, ask suppliers to provide:

Torque curves for different operating conditions

Life test results or durability data

Recommended service intervals

Dimensional drawings and mounting diagrams

This documentation helps verify that the gearbox can meet both current and future operational needs.

Consider supplier offerings related to warranty coverage, international certifications (CE, ISO), and availability of on-site support. Confirm lead times for spare parts to prevent operational disruptions. A reliable supplier partnership ensures long-term performance and service continuity.

Selecting the right Industrial Inline Helical Gear Reductor requires careful analysis of conveyor load, duty cycles, ratio, mounting options, environmental conditions, efficiency, and maintenance considerations. Taixing’s expertise in inline helical gear technology allows us to provide high-performance gear reducers tailored for diverse conveyor applications. By following this detailed checklist, engineers can confidently short-list models, anticipate maintenance needs, and request precise quotes that match their system specifications. Contact us today to upload your conveyor specifications and get a tailored recommendation that ensures optimal performance, durability, and operational efficiency.