Views: 0 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

Industrial Inline Helical Gear Reductor units are essential components in modern manufacturing, providing a reliable solution for power transmission with high efficiency, durability, and smooth operation. Factories increasingly select inline helical gearboxes because they offer quieter performance, better load-handling capabilities, and easier integration into complex machinery setups. At Taixing, our R Series inline helical gear units demonstrate these advantages, combining modular design with high-quality engineering to optimize factory machinery and reduce downtime.

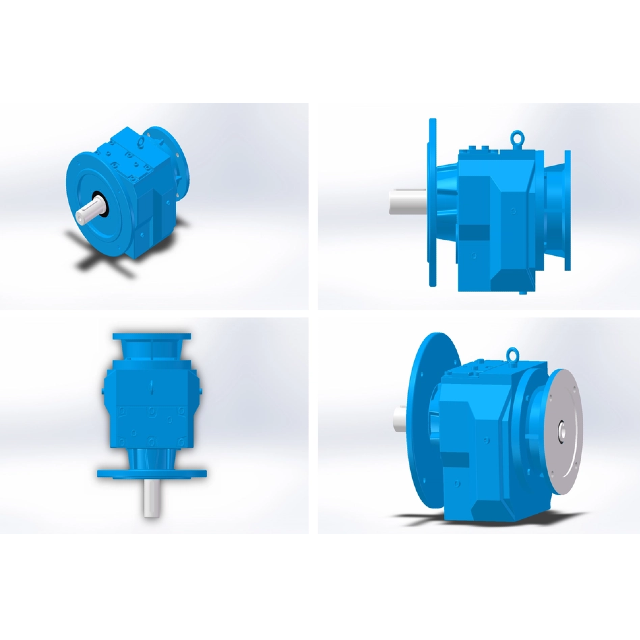

An Industrial Inline Helical Gear Reductor is a gearbox in which the input and output shafts are aligned in a straight line. It uses helical gears with angled teeth that engage gradually along their width, distributing loads across multiple teeth simultaneously. This design reduces shock loads and wear while increasing operational life. Modern units, like Taixing’s R Series, also feature modular construction, enabling factories to customize gear ratios, torque ratings, and mounting options without complex redesigns. Modularity allows for quick replacements, straightforward retrofits, and consistent performance across different machinery setups, making it a versatile choice for industrial operations.

To imagine how an inline helical gearbox works, picture power entering through the input shaft, transferring through helical gears arranged in-line, and exiting via the output shaft. The helical teeth mesh gradually, maintaining continuous power flow while reducing vibration and noise. This smooth engagement ensures stability and efficiency in high-speed conveyors, heavy-duty mixers, and other machinery requiring reliable torque transmission.

Helical gears engage gradually along the length of the teeth, unlike spur gears that mesh abruptly. This gradual engagement results in reduced shock loads and significantly lower vibration and noise levels during operation. Factories operating in noise-sensitive environments, such as packaging or food processing plants, favor inline helical units because they help maintain a safe and comfortable work environment while protecting equipment longevity.

Because multiple teeth share the load simultaneously, helical gearboxes can transmit higher torque levels without excessive wear. This load distribution improves durability, reduces maintenance frequency, and ensures consistent performance under continuous or fluctuating loads. Industries such as cement, mining, and quarry operations benefit from this characteristic, as their machines often operate for long periods under heavy stress.

While worm gear reducers are compact and can offer self-locking benefits, they are generally less efficient than helical units, especially at higher ratios or sustained loads. Inline helical gearboxes typically achieve higher mechanical efficiency, reducing energy losses and heat generation. This efficiency translates into lower operational costs, less downtime due to overheating, and more reliable long-term performance. Factories with energy-conscious goals often prioritize inline helical gear units for these reasons.

The modular design of modern inline helical gear units simplifies inspection, lubrication, and part replacement. Bearings, seals, and gear sets can be serviced or replaced without dismantling the entire gearbox. This feature reduces downtime, allows predictive maintenance schedules, and helps factories avoid unexpected interruptions in production lines.

Inline helical gearboxes are widely used in belt conveyors, screw conveyors, and automated material handling systems. Their inline shaft alignment simplifies connection to standard motors, reducing the need for additional coupling components or angled shafts. Smooth and quiet operation makes them ideal for industries like warehousing, logistics, and automotive assembly, where uninterrupted material flow and minimal noise are crucial.

Industrial applications such as crushers, mills, and cement plant machinery demand gear units capable of handling extreme loads and abrasive conditions. Inline helical gear reducers excel in these environments because of their robust construction, high torque capacity, and shock-absorbing helical teeth design. Their durability ensures equipment remains operational even in demanding, dusty, or high-vibration conditions.

Inline helical gearboxes are used extensively in packaging lines, bottling systems, and conveyor setups where precision, quiet operation, and consistent performance are essential. In food and beverage processing, these units help maintain hygiene standards by operating smoothly and reducing contamination risk from excessive vibration or heat. Their efficiency ensures production lines run faster with lower energy consumption, supporting both operational and environmental goals.

Beyond traditional heavy industry and packaging, inline helical gear units find use in textile machinery, printing presses, chemical processing, and wastewater treatment plants. Anywhere precise speed control, load management, and energy efficiency are required, these gearboxes deliver reliable performance.

Inline helical gearboxes are ideal when factories require high load capacity, extended service life, low noise, and efficient power transmission. They are well-suited for continuous duty applications or processes that demand smooth operation under variable or high torque loads. Inline designs also simplify motor mounting and shaft alignment, making them preferable in systems where precision and ease of installation matter.

Worm gearboxes are advantageous in low-speed, low-power applications where self-locking or compact installation is critical. Bevel gear units excel at transmitting torque at angles, often in confined spaces where inline orientation is impractical. While these designs are cost-effective for specific scenarios, they typically cannot match the load-handling efficiency, quiet operation, and long-term durability of inline helical units for heavy industrial use.

When evaluating an inline helical gearbox, it is important to check:

Rated power and torque capacity

Gear ratio

Mounting type (foot, flange, or combination)

Input and output shaft dimensions

Protection rating (IP) for dust and water

Thermal limits to avoid overheating during continuous operation

Understanding these specifications ensures compatibility with existing machinery, prevents overloading, and helps in selecting a unit that meets both performance and maintenance expectations.

Modular gear designs, like Taixing’s R Series, make retrofits and replacements straightforward. Factories can adjust ratios, mounting styles, and torque ratings according to operational needs, reducing lead times and installation complexity. This flexibility also supports standardization across multiple production lines, helping factories maintain consistent performance while minimizing spare parts inventory and downtime.

When choosing a gearbox, consider the duty cycle, operating environment, and alignment requirements. Inline helical units with modular features allow incremental upgrades, making them suitable for evolving production processes or expanding industrial facilities.

Industrial Inline Helical Gear Reductor units deliver efficient, quiet, and durable performance across a wide spectrum of industries. With advantages in load distribution, smooth operation, and energy efficiency, they are ideal for conveyors, heavy processing, packaging, and other applications requiring reliable torque transmission. Taixing’s R Series inline helical gearboxes combine modularity, high-quality engineering, and ease of integration to help factories maximize productivity and minimize maintenance challenges. For engineers and procurement teams exploring gear solutions, reviewing datasheets, comparing ratios, and contacting a trusted supplier like Taixing ensures the right unit for specific operational needs. Contact us today to explore our Industrial Inline Helical Gear Reductor range and download technical specifications tailored to your requirements.