Views: 0 Author: Site Editor Publish Time: 2025-09-23 Origin: Site

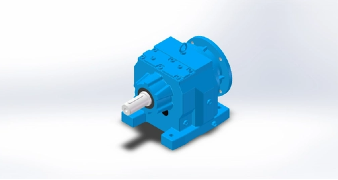

Keeping your production lines running efficiently requires reliable power transmission components. The R Series Industrial Inline Helical Gear Reductor from Taixing is engineered to provide smooth, consistent performance in a wide range of industrial applications. Designed with precision engineering and advanced materials, this gear reducer ensures durability even under heavy-duty conditions. This guide provides practical, field-tested steps for installation, maintenance, and troubleshooting to help maintenance engineers and installers maximize equipment uptime and operational life, while safeguarding long-term operational efficiency.

Before beginning installation, carefully inspect the R Series inline helical gear reducer upon delivery. Verify that the packaging is intact and free from any signs of damage during shipping, as even minor dents can affect gear alignment. Confirm that serial numbers match the purchase order to ensure you have received the correct model. Check the oil fill level and verify that it aligns with the manufacturer's recommendations; some models may arrive pre-filled, but shipping may cause minor oil displacement. Additionally, inspect shaft alignment tolerances and ensure there is no visible shaft damage or excessive play. Accurate inspection at this stage prevents installation issues that could compromise performance and lifespan.

The R Series gear reducer supports multiple mounting orientations, making it adaptable to different industrial setups. Confirm the correct orientation before installation to ensure proper lubrication flow and efficient heat dissipation. Review all supplied accessories, including mounting feet, flanges, keyways, and alignment adapters, ensuring that none are missing or damaged. Modular components facilitate flexibility, allowing for easier future adjustments or retrofits without full disassembly. Checking these details beforehand reduces setup time and prevents alignment problems that could lead to premature wear.

Accurate mounting is essential for the longevity of your R Series inline helical gear reducer. Ensure the mounting surface is perfectly flat and level to prevent unnecessary stress on the gearbox. Fasteners should be torqued according to the manufacturer’s specifications to maintain proper clamping force without distorting the housing. Use calibrated torque wrenches to guarantee precision. Proper coupling alignment between the motor and reducer shafts is critical; misalignment can accelerate gear and bearing wear, increase vibration, and reduce efficiency. Employ dial indicators, laser alignment tools, or precision shims to achieve optimal alignment. Documenting measurements can help track alignment over time and prevent recurring issues.

After mounting, perform a vibration check to detect any irregularities that may indicate misalignment, unbalanced couplings, or assembly errors. Excessive vibration can lead to early gear tooth damage or bearing fatigue. Conduct an initial run-in procedure under light load for a specified period, allowing gears and bearings to settle into optimal positions. Gradual load ramp-up during the first operation helps reduce mechanical stress and ensures that lubrication reaches all critical contact surfaces. This practice also provides an opportunity to listen for abnormal noises, verify temperature stability, and adjust oil levels if necessary.

Maintaining the correct lubrication is critical for the reliable operation of the R Series inline helical gear reducer. Use the lubricants specified by Taixing, which are designed to withstand industrial load conditions and high temperatures. The initial oil change is usually recommended after the first 100 hours of operation to remove any debris or machining residues. Subsequent changes should follow operational hours or annual schedules, adjusted for temperature extremes or contamination risks. Proper lubrication reduces wear, lowers energy consumption, and extends the life of gears and bearings.

Routine inspections help detect issues before they result in downtime. Daily checks include monitoring operating temperature, listening for unusual noises, and observing vibrations. Weekly inspections should include checking oil levels, signs of leaks, and minor oil contamination. Monthly maintenance involves measuring gear backlash, checking bearing conditions, and examining seals for wear or hardening. Keeping a detailed log allows engineers to identify trends, predict maintenance needs, and optimize preventive measures. Incorporating these routines into the factory’s maintenance plan ensures long-term reliability and minimizes unexpected failures.

Overheating can occur due to overloading, misalignment, or insufficient lubrication. Address these issues by adjusting the load, ensuring proper oil level and type, and correcting any misalignment. Abnormal noises, such as grinding, clattering, or whining, often indicate wear or damage to gears, bearings, or couplings. Oil contamination may result from seal leaks, debris ingress, or extended intervals between oil changes. Early detection is critical: taking corrective action quickly prevents minor issues from escalating into major failures that disrupt production.

Regular component inspections distinguish between gear, bearing, or seal failures. Gears should be examined for pitting, scoring, or abnormal wear patterns, while bearings should rotate smoothly without excessive play or heat. Seals need to be checked for cracks, leaks, or hardening that could compromise lubrication. In case of serious internal damage, contact Taixing’s technical support to determine whether factory-level repair or replacement is required. Proper documentation of inspection results aids in predictive maintenance and ensures continuity of operations with minimal downtime.

Maintaining a stock of essential spare parts ensures fast repairs and reduced downtime. Common items for the R Series inline helical gear reducer include seals, bearings, and gear sets. The modular design allows for the replacement of individual components without disassembling the entire unit. This capability is especially valuable in high-usage industrial environments, where quick intervention is necessary to maintain production schedules. Stocking critical spares in advance also reduces lead time and production interruptions.

Retrofits and upgrades can significantly improve operational performance. Consider higher-efficiency gear sets, sealed housings for harsh or washdown environments, or advanced lubrication systems to reduce maintenance intervals and enhance reliability. Upgrading older units with modern components extends their service life and helps industries meet increasing efficiency and energy-saving requirements. These enhancements contribute to overall cost savings while improving process stability.

Following proper installation, maintenance, and troubleshooting procedures ensures that the R Series Industrial Inline Helical Gear Reductor from Taixing delivers consistent, long-term performance. By performing thorough pre-installation checks, adhering to alignment and lubrication best practices, and keeping essential spare parts on hand, maintenance teams can minimize downtime and extend the mean time between failures. For further guidance, detailed maintenance checklists, or to request spare parts, contact us and let Taixing support your operations with reliable gear reduction solutions.